The fifth process of magnet production: isostatic pressure

Molding field oriented link to neutralize the green density of about 3.2 3.8 g/cm after, and the ideal of sintered ndfeb magnet density should be 7.5 g/cm after the left and right sides, when pressing larger cylindrical and square so easily because of its high shrinkage crack,...

The second process in the magnet production process: hydrogen crushing

The rare earth raw material of the magnet is cooled by smelting and smelting in the melting furnace to make a strip, and then enters the hydrogen crushing section, which is the coarse crushing and medium grinding of rare earth alloy. The feed size is 100-- 0.1mm, and the output...

Can a strong magnet stick to stainless steel?

Iron and steel are usually distinguished by the amount of carbon they contain.An iron-carbon alloy with less than 2% carbon is steel, and an alloy with more than 2% carbon is called iron.Steel is widely used because of its toughness, elasticity and rigidity.Life is all steel, but...

Process of magnet production: smelting

Smelting is the first process to produce sintered NdFeb strong magnet. The smelting furnace produces an alloy sling strip. The process requires the furnace temperature to reach 1300 degrees Celsius and lasts four hours to complete.After this process, the raw materials of the...

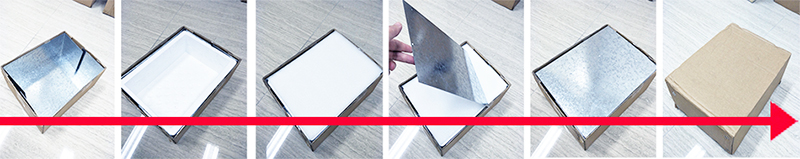

Degaussing packaging of magnets

The so-called degaussing, in fact, the magnetic did not disappear, just through the magnetic material to change the magnetic field distribution of the magnet.

The degaussing package is usually isolated by iron sheet. The six sides inside the box are fixed, and then the pearl...