Understanding Magnet Grades and Magnet Tables

Each day we get asked questions about the differences in magnetic materials. Neodymium Magnets, Samarium Cobalt (SmCo) Magnets, Ceramic Magnets, Alnico Magnets, Bonded Magnets, and Injection Molded Magnets all have various options, and choosing the correct grade for your application is critical.

Usually before quote,when we assist customers with magnet selection we will undoubtedly ask questions about the application. This helps us understand the environment and requirements of the magnet. But, in about 50% of the situations, our customers are not able to make known the application due to Confidentiality and Privacy reasons. If this is the situation, we will then ask such questions as:

What is the temperature that the magnet will be exposed (maximum operating temperature)?

What other materials (i.e. steel, aluminum, plastic, etc.) will the magnet be next to?

What is the size of the area for the magnet?

What are the tolerances required?

Is the magnet in an assembly or operating independently?

Are there specific coating requirements?

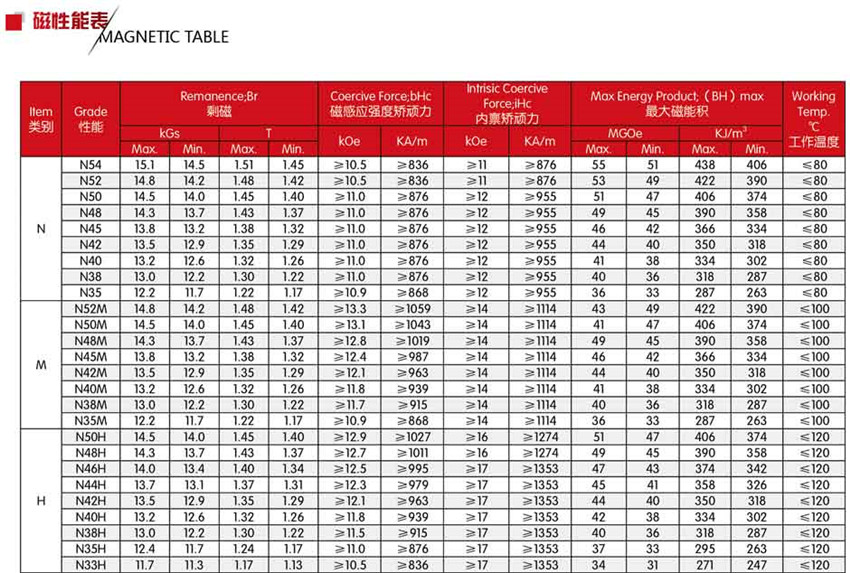

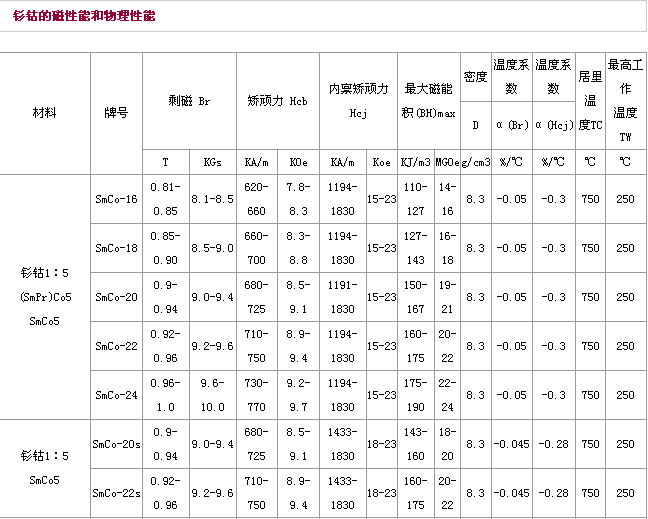

Neodymium Magnets and Samarium Cobalt Magnets are available in many grades. There are several factors and considerations that go into design, but for this article, the areas discussed will be Magnet Strength, Magnet Coercivity, and the Considerations for Magnet Selection.

The strength of a magnet can be found in the magnet specification known as BHmax, which is the maximum energy density of a magnet. This is defined in Mega Gauss Oersteds, or MGOe. On a Magnetic Demagnetization Curve this is the highest point of the magnet’s strength, or the magnet’s maximum energy product.

For Neodymium (NdFeB) Magnets the BHmax will range, in general, from 30 MGOe to 55 MGOe. So, when defining your magnet need, keep in mind that the higher the number, the stronger the magnet. Neodymium magnets produce the highest MGOe of any permanent magnet material. The most common grades of Neodymium magnets are N35, N38, N40, N42, N45, N48, N50, N52, and N55.. The number 'M-H 'usually indicates the degree of resistance to high temperatures.

Understanding Magnet Grades and Magnet Tables. If you have more questions about magnet-making or products, Welcome contact Jugo Magnet freely!

+Dongguan Jugo Magnet Co.,Ltd

+Contact: Ms.Wendy

+Email: wendy@jugomagnet.com

+Skype: jugosales