Magnet production process of the eighth process: mechanical processing

Magnetic mechanical processing division:

(1) Punching and holing: The round bar and square bar magnet are punched and processed into cylinder or square barrel magnet

(2) Slicing: Cylindrical and square columnar magnets are cut and processed into circular or square pieces by slicing machine

(3) Shape processing: The round and square magnets are processed into tile, sector, groove or abnormal-shaped magnets and other complex shapes

Its shape slicing processing method is as follows:

Grinding slice processing, internal slice machine slice, multi - line cutting slice, wire cutting special-shaped processing

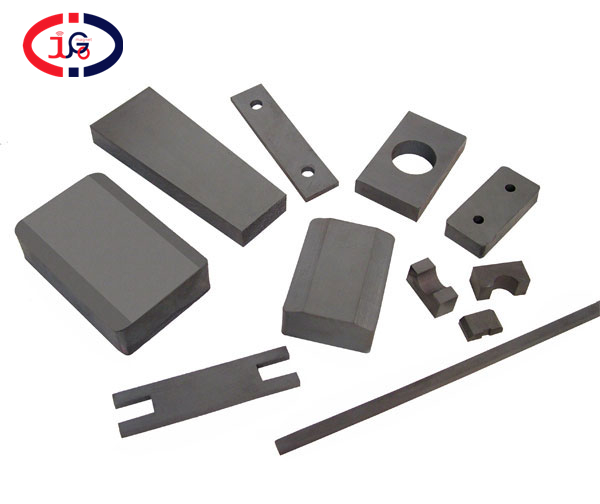

In practice, the properties and shapes of NdFeb magnets are various, such as: disc, disc (counterhead screw hole), cylinder, ring, cylinder (with inner hole), square, sector, tile, trapezoid, groove, polygonal polygon and irregular shape, etc.Each magnet of different shape has different size, performance, tolerance value, and magnetized direction.It is difficult for magnets to be machined in one go during the production process.

More question of ndfeb magnet, Welcome contact Jugo Magnet freely!

+Dongguan Jugo Magnet Co.,Ltd

+Email: sales@jugomagnet.com