Salt spray test standard for nickel-plated ndfeb magnet

The salt spray test standard for nickel-plated NdFeB magnet is a specific specification for the salt spray test conditions, such as temperature, humidity, concentration of sodium chloride solution and PH value.The salt spray test standard for the same product shall be selected according to the characteristics of the salt spray test, the corrosion rate of the metal and the sensitivity to the salt spray.

Several salt spray test standards are introduced:

GB/T2423.17 -- 1993 basic environmental test procedures for electronic and electrical products test Ka: salt spray test method;

GB/T2423.18 -- 2000 environmental testing of electrical and electronic products -- part 2: experimental testing Kb: salt spray, alternating (sodium chloride solution);

GB5938-86 test method for corrosion resistance of metal coatings and chemical treatment of light industrial products;GB/T1771 -- 91 determination of resistance of paints and varnishes to neutral salt spray.

Test methods: 1. Use 5+/-1% NaCl solution; 2.2. Set the temperature at 35°C;3. The PH value is 6.5~7.2;4. The salt spray precipitation is 2+/-1ml/80cm2/h;5. The duration of the test was 48h.Test criteria: the surface treatment layer should be free from oxidation, peeling, fading, rust, corrosion and other phenomena.

The purpose of salt spray test is to examine the quality of products or NdFeB magnet to resist salt spray corrosion, and the determination of salt spray test result is the judgment of product quality, whether the determination result is correct and reasonable is the key to correctly measure the quality of products or metal to resist salt spray corrosion.

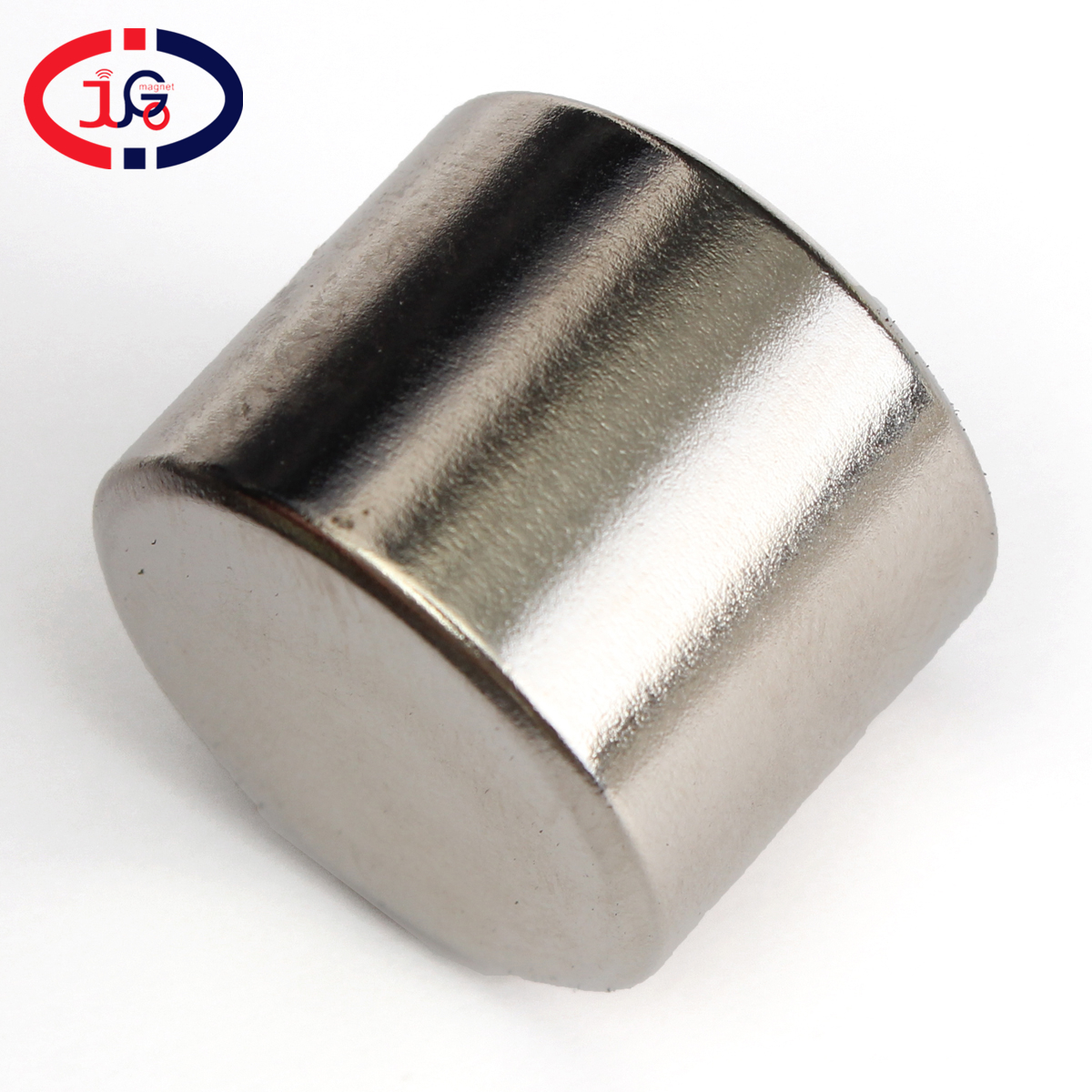

After 48 hours of salt spray, we generally recommend customers to use nickel plating. At present, the basic process of nickel plating is nickel-copper-nickel, so as to ensure that the magnet will not be damaged in the case of corrosion.

Jugo Magnet is a rare earth magnet manufacturer with many years of experience in China.More question of nickel-plated ndfeb magnet, Welcome contact Jugo Magnet freely!

+Dongguan Jugo Magnet Co.,Ltd

+Contact: Ms.Wendy

+Email: wendy@jugomagnet.com

+Skype: jugosales